how much wire to leave in a junction box The Minimum Size Junction Box for Electrical Wiring. Part (1) of Section 370-16 (a) describes in detail the method of counting wires, as well as clamps, fittings, or devices (i.e., switches, receptacles, combination devices) - by establishing an . Choose Quickparts for all your custom prototyping and low-volume production parts. Attend our local events to discuss with our experts about our comprehensive Injection Molding capabilities, NEW CNC Express, and 3D Printing. Introducing CNC Express: Get an instant quote and shipping in as fast as 2 days!

0 · maximum wires in junction box

1 · maximum wires in electrical box

2 · junction box wiring guidelines

3 · electrical junction box wiring diagram

4 · electrical box wire size chart

5 · electrical box wire fill chart

6 · electrical box wire counting chart

7 · 12 wire box fill calculator

From attractive, extremely durable garage cabinets to slatwall to overhead racks, GarageCabinets.com has everything you need to get your garage organized for good. You'll deal directly with the manufacturer, so we can pass the savings on to you.Get instant online quote for your metal or plastic CNC machined parts, from rapid prototyping to production. Tolerance down to 0.001 inches. Choose from 100+ materials, 60+ surface finishes.

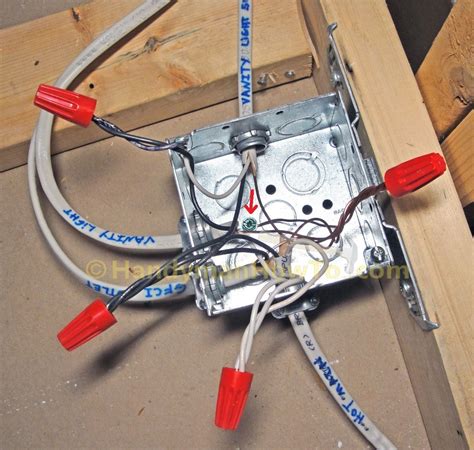

At least 150 mm (6 in.) of free conductor, measured from the point in the box where it emerges from its raceway or cable sheath, shall be left at each outlet, junction, and switch point for splices or the connection of luminaires or . In general, you should leave at least 6 inches of wire in the junction box. When the wire is in a horizontal line, it should come out 3 inches from the opening, and the other 3 . When electrical cables route from box to box, you must leave at least six inches of free conductor wiring in the junction box for connection purposes. In article 300.14, this technique is explained.The Minimum Size Junction Box for Electrical Wiring. Part (1) of Section 370-16 (a) describes in detail the method of counting wires, as well as clamps, fittings, or devices (i.e., switches, receptacles, combination devices) - by establishing an .

At least 6 inches of free conductor, measured from the point in the box where it emerges from its raceway or cable sheath, shall be left at each outlet, junction, and switch point for splices or the connection of luminaires or devices.Here’s a step-by-step approach to figure out the wire capacity of your junction box: Measure the Box: Start with the basics. Know the size of your junction box—this is your starting point. Identify Wire Gauge: Determine the gauge of .

How to Count Wires in an Electrical Box . Count the wires and other components within an electrical box to determine if the current setup or planned additions will fit the electrical box. Start by finding the electrical box . Be sure to use the correct size wire nut: if the nut is too small, the wires won’t fit, and if it’s too big, the wires could loosen and fall out. Wire nuts are color-coded for AWG and capacity, both of which are also listed on their .

sheet metal license test

Yield: Install an electrical junction box. Skill Level: Intermediate. Estimated Cost: to . Installing an electrical junction box gives you freedom and flexibility when installing electrical cables. It's often used when an . Wire Stripper Tool I Use: https://amzn.to/2yQMWV9When pulling wire into an electrical box it is important to leave yourself plenty of wire but not too much e. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright . When electrical cables route from box to box, you must leave at least six inches of free conductor wiring in the junction box for connection purposes. . Below are some things to consider when trying to figure out how much wire to leave in outlet box. How Long Must Wires Be in an Electrical Box? (2020 NEC .

Here is what the only book that counts says 300.14 Length of Free Conductors at Outlets, Junctions, and Switch Points. At least 150 mm (6 in.) of free conductor, measured from the point in the box where it emerges from its raceway or cable sheath, shall be left at each outlet, junction, and switch point for splices or the connection of luminaires or devices.Your third option is to do it the right way and run a new wire back to the breaker box. Reply reply moduspol • Or even just to a place where you CAN put a junction box and leave it accessible (like a crawl space or something). I think you can also use a paintable access panel and then stick a junction box behind there, although obviously the . How much wire is required at an outlet box? Today I'll show you in this short video what the NEC requires for wire at an outlet box. How much from inside the. Your best bet it to put in a junction box where you would have coiled the wire. That way you can remove / abandon the wire to the switch, and run new wire to the new switch when you build the wall. . With the price of wire today, it might actually be cheaper to buy an extra box, cover & wire nuts than leave 8'+ of copper laying unused .

Connecting Wires Inside the Junction Box. Carefully strip the insulation from the wires and connect them inside the junction box using wire connectors. Follow the manufacturer’s instructions for proper installation. Pay attention to color coding and ensure a secure connection. Properly Securing and Grounding the Junction Box

Make sure the ground is bonded with the metal box so it doesn't get become tingly if the wire nut falls of the hot. The pretty way to do it is with a green 10-32 screw. (Edit: the single bear copper wire in there leads me to believe that it might be bonded already, just double check) Use a "1900 box metal blank cover"

The process of extending electrical wires with a junction box is fairly simple and can be done by anyone with a basic knowledge of electrical wiring. In this article, we'll explore the steps involved in extending electrical wires from an existing circuit with a junction box and offer some tips to ensure the job is done correctly. Overfilling Electrical Boxes Mistake: Too many wires in a junction box. Stuffing as many wires as possible into an electrical box is a fire hazard. Solution: Follow box fill requirements. The NEC limits the number of wires, devices, clamps and other accessories inside electrical boxes.I googled and found electrical tape, wire nuts and a junction box the best way to make wires not in use safer apart from detaching from the source. Is it better for the wires to be in a junction box? I tested to see if the wires were live and my detector went off slightly. Is it still safe to leave in wire nuts/a junction box and seal up in the .The wires need to enter the box with the jacket or have bushings. The metal knockouts are going to create friction and expose your wires if you don’t. You need to ground the box. You need to get all copper currently exposed outside the box moved inside and .

Wires from an old panel which is now a junction box. The wires are not connected to any circuit breaker. W. winnie Senior Member. Location Springfield, MA, USA Occupation Electric motor research Oct 30, 2017 #13 IMHO: If a wire is in a box at both ends, and could potentially be energized (eg. a spare conductor) then it needs to be insulated .

Like everyone else said, put a wire nut on each wire, and put the wire inside a plastic junction box. If you are too lazy to put in a junction box, at least put on the wire nuts. In honesty, the tape is probably fine and likely 99.999% safe, but .How to Wire a Junction Box: Selecting a Junction Box for Electrical Wiring, The Basics of Electrical Junction Boxes, The number of wires that are allowed in a Junction Box. Top of List DIY Home Electrical Wiring Projects. Smart Light .In general, yes. Note, however, that you're supposed to leave "access" to any junction box, per code. So, if it's enclosed in a ceiling (as opposed to in an open attic or something), there is supposed to be, at the minimum, a panel to access the junction box.

The rule for leaving a 1/4" of sheathing on the cable on the inside of the box probably stemmed from those who always cut too much sheathing off. To me the exact measurement of at least 1/4" of sheathing on the inside of the box is not really critical as long as there is at least some. It's when the sheathing doesn't make it into the box, or, at times, even .

There’s a junction box on the brick wall outside the home, and power enters the outlet from the box. I figure there’s a proper weather proof junction box suitable for coaxial and power that I can use outside, but I’m having trouble finding one. Inside, my plan is to replace the 1 gang junction box in the built-in bookcase with a 2 gang box. Wire expansion/contraction in conduit is quite minimal. I’ve never left more than the few inches you normally get when you don’t straightline through a junction box. Part of the reason 6/3 is so stiff is it’s not intended to be run in conduit. It’s intended for direct underground burial.

Ran across this junction box under my new Forest River "Salem" FSX 177BH while doing some extra "hole plugging" with foam sealer. It is located just behind the hitch. Can I assume . Then several wires leave the box, so those might be feeding your electric brakes, or any number of other things. That box is a standard j-box for house and .In commercial work there is almost always a gutter box above the panel. If re work or changes need to happen then people can pull the old wire out of the panel and splice a longer wire on to go to whatever breaker they want. . than the hot wires not reaching a breaker. I'll leave a small amount of slack on anything #8 or larger, because they .Any wires capped off like that have to be inside a junction box other enclosure. If you know the breaker, and that's the only outlet on the breaker, you can disconnect and remove as much as you can easily reach at the breaker box side, then do the same at the outlet side. You can leave the unused wire laying under the floor.

Just write on it with Sharpie, then slip it over the wire. Then again, there's always the labeling solutions built for the purpose. Brady is standard in my work (datacenter), but I use Dymo at home. Both the labeler and tape are a little cheaper. I use nylon cloth tape pretty much exclusively (it's "UL recognized").

That unused cable will need to terminate in a 4x4 metal junction box with a cover. I would screw the box down to the top of the cabinet and the cable [Romex or MC] will need to be attached with the right connector. The cable will then need to be stripped to expose each wire then each wire capped tightly with a wire nut.

That reduces the chances of the splice pulling apart. But, just in case it does, and the wires become exposed, the box is grounded. So, the live wires will hit that grounded box and the wire will see a near 0 ohm connection to ground, which will instantly flip the breaker, and reduce your chances of a fire to near zero.

Run wires through new junction box with romex clips to secure the wire. Connect black to black, white to white, and ground to ground with a pigtail to the box for the ground wire only. Twist them together securely and then twist a wire nut on the end of each wire. Screw cover plate on new junction box and continue your work.

maximum wires in junction box

When it comes to finding a reliable wholesale sheet metal punching parts factory, look no further! Our factory is dedicated to providing high-quality metal fabrication services tailored to meet .

how much wire to leave in a junction box|electrical box wire counting chart